GEOMETRIC flexible Disc Couplings are torsionally rigid type with zero backlash. Torque is transmitted through pure tension in flexible elements. Flexibility is achieved by flexing elements due to bend between the Drive and Driven bolts and has NO Relative Motion Between Coupling Components hence it requires “NO LUBRICATION”. Reliability of Flexible Disc couplings are very high compared to all other types of couplings include Gear. Disc couplings are maintenance friendly compared to other types. Example for the replacement of Flexible elements in the coupling NO-NEED to disturb the equipment foundation & NO-NEED to remove HUB from the equipment shaft. Low thrust loads and low bending moments on equipment shafts due to misalignment during running. Flexible Disc couplings are Ideal for: STEAM TURBINES, GAS TURBINES, PUMPS, FANS, COMPRESSORS, PAPER MILL Drives etc.

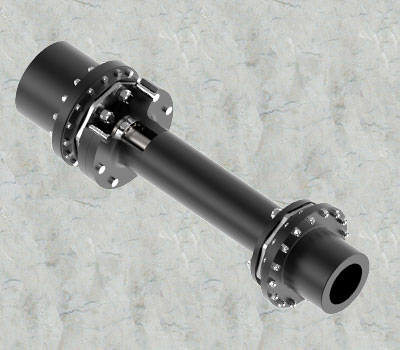

Standard Coupling Design consisting two hubs connected with one spacer and two flexing elements as shown. one hub is mounted on Drive shaft and other is on Driven shaft along with center spacer connected by two flexible elements stacks. These couplings are suitable for PUMP Drives, FAN Drives, PAPER MILL Drives etc.

Applications:

✦ Boiler Feed Pump

✦ Paper Machines

✦ I.D Fans

✦ F.D Fans

✦ Compressors